The Importance of a Robust Quality Management System (QMS) at AMT

Engineered for Purity: AMT’s Medical-Grade Clean Room Assembly Services in Singapore

Contamination of medical devices can be traced back to assembly or transport in around 70% of cases. This underscores the critical role that cleanroom assembly plays in ensuring both patient safety and securing product approvals.

AMT Medical Clean Room Assembly Services in Singapore possesses over 30 years of experience in https://amt-mat.com/cleanroom-vs-white-room-assembly-for-medical-device-manufacturing/. Their workforce of roughly 350 people serves clients in over 30 nations worldwide. This makes Singapore as a central location for medical clean room construction and precise assembly work.

AMT is certified in ISO 13485, ISO 9001, and IATF 16949. They follow strict quality systems to assist with regulated device programs. Their facilities are equipped for Class 100K (ISO Class 8) clean rooms. They also offer services like single-site injection molding, tooling, and assembly. This reduces the risk of contamination and streamlines the process.

This article covers how AMT’s services for medical clean room assembly help with meeting regulatory requirements. Furthermore, it details their methods for managing microbial control and integrating various processes. These efforts assist medical manufacturers speed up their product market launch. They also serve to protect the sterility of products and safeguard intellectual property.

Overview of AMT Medical Clean Room Assembly Services

Based in Singapore, AMT Pte. Ltd. has served as a trusted partner in the manufacturing of medical devices for over three decades. They work with clients from more than 30 countries and have robust ties with suppliers in Asia. The Singapore headquarters employs about 350 local staff members to offer regional support.

AMT is known for its high-quality standards, thanks to key certifications. ISO 13485 ensures their processes meet medical device regulations. ISO 9001 guarantees quality management across all operations. Their IATF 16949 certification showcases their proficiency in automotive-grade process control, which is a great benefit for assembling medical devices.

One of AMT’s key strengths is its single-site integration. They handle tooling, 3D metal printing, metal and ceramic injection molding, and clean room assembly all in one location. This method leads to shorter lead times and a reduced risk of contamination.

Both sterile and non-sterile products can be handled by AMT’s clean room assembly services. The integrated workflows they use for molding, inspecting, packaging, and assembling result in better traceability and quality control. As a result, production runs more smoothly.

For clients who need assembly in controlled settings, AMT’s vertical integration model offers a substantial benefit. Positioning tooling and molding operations near the cleanroom reduces the steps involved in handling. This also simplifies logistical challenges and guarantees consistent control over the environment.

AMT’s Services for Medical Clean Room Assembly

Medical clean room assembly services are offered by AMT. These offerings are designed to help medical device manufacturers located in Singapore and the surrounding regions. They focus on clean production in ISO Class 8 areas. Here, parts are made, assembled, and packed with strict cleanliness rules. Comprehensive services for molding, assembly, validation, and microbial testing are provided by AMT.

Definition and primary services offered under this keyword

AMT specializes in medical clean room assembly. This work is done in specialized cleanrooms for parts of medical devices. Key services include cleanroom molding, component assembly, final packaging, environmental monitoring, and microbial testing. AMT assists in producing parts for surgery and devices that need a clean environment.

How Class 100K (ISO Class 8) cleanrooms support device manufacturing

Class 100K cleanrooms keep the air clean enough for many types of assembly. This helps prevent particle contamination in devices like parts for endoscopes. AMT inspects the air, pressure difference, humidity, and temperature on a regular basis. This helps them stay compliant and keep detailed records.

Advantages of Vertical Integration in Controlling Contamination and Logistics

Having molding and assembly in the same facility helps prevent contamination. This results in reduced lead times and simplified quality inspections. The method used by AMT minimizes problems, improves traceability, and leads to cost savings from reduced transportation.

This approach ensures that AMT’s production processes stay clean and efficient. It makes for better products and simpler paperwork for manufacturers. They trust AMT with their needs.

Cleanroom classifications and compliance for medical device assembly

Understanding cleanroom classes helps to match the right environment to product risks. Cleanroom assembly compliance relies on setting clear particle limits, doing regular checks, and having proof of validation. This section delves into the standards for ISO Class 8. It also covers monitoring methods that keep medical assembly lines up to par in Singapore and other locations.

ISO Class 8 requirements

The maximum allowable concentration of airborne particles, categorized by size, is defined by ISO Class 8 cleanroom standards. For numerous medical device assembly tasks that do not require absolute sterility, these cleanrooms are ideal. The industry often calls it Class 100K. This designation is commonly used for tasks involving plastic injection molding and assembly.

Validation and monitoring practices

For medical cleanrooms, regular environmental monitoring is crucial. Facilities keep a close eye on air particles to make sure they are within set limits.

Teams check the pressure difference between areas to keep the air moving correctly. They also control temperature and humidity to prevent product damage and reduce the chance of contamination.

They do regular validations and keep detailed records to demonstrate they are following rules. Special teams check for microbes to spot any problems early and address them when necessary.

Alignment with Regulations

Meeting the rules set by bodies like the US Food and Drug Administration and the European Medicines Agency is vital. Keeping ISO 13485 certification and detailed validation records is essential for passing audits and making regulatory filings for device makers.

Thorough documentation of cleanroom procedures, regular requalifications, and data tracking demonstrate to inspectors that manufacturers have full control. Building medical cleanrooms to these standards simplifies regulatory checks and speeds up time to market.

Integrated manufacturing: injection molding and clean room assembly

The production of medical equipment becomes more efficient when both molding and assembly are performed at a single site. It means less moving around inside the facility. Plus, it makes it easier to keep an eye on quality, from the molding to the final packaged product.

Advantages of single-site integration

When both injection molding and assembly are done together, handling of parts is significantly reduced. This results in faster development of prototypes and a quicker production startup. It facilitates close cooperation between the tooling, molding, and assembly teams. This ensures the quality checks meet the same high standards.

Minimizing Contamination Risk and Saving on Logistics Costs

The risk of contamination is lowered by eliminating the need to move items between different locations. There is also a reduction in costs associated with packaging, shipping, and handling. Having everything in one place makes it easier to manage quality control and follow regulations. This makes clean room assembly more efficient.

Product Type Examples Ideal for Integrated Processes

Products like endoscopic pieces, housings for surgical instruments, and parts for minimally invasive devices do well in this integrated system. Depending on the sterilization and packaging, both sterile and non-sterile items can be made.

| Type of Product | Main Benefit of Integration | Typical Controls |

|---|---|---|

| Lenses and housings for endoscopes | Less particle transfer from molding to optics assembly | ISO-classified assembly areas, particle counts, validated cleaning procedures |

| Housings for surgical instruments | Better dimensional control and batch traceability | In-line inspections, material lot tracking, validation of sterilization |

| Components for minimally invasive devices | Efficient change control for fast design updates | Controlled environment molding, bioburden testing, process documentation |

| Disposable diagnostic housings | Lower logistics cost and faster time-to-market | Supply chain consolidation, batch records, final inspection |

Opting for a facility that manages both clean room assembly and cleanroom injection molding ensures improved quality control and dependable production schedules for medical devices. This approach minimizes risks and preserves value, from the first prototype to the final product shipment.

Use Cases and Environment Choices for Medical Device Assembly

It is essential to select the appropriate environment for medical device assembly. AMT offers options from strict ISO-classified rooms to controlled white rooms. This adaptability allows for matching the assembly process to the risk level of the specific device.

Choosing Between a Cleanroom and a White Room for Assembly

An ISO-classified cleanroom should be used when particular levels of cleanliness are necessary. This applies to devices such as implants and sterile disposable products. They are protected during assembly and packaging in cleanrooms.

If higher particle counts are permissible, white room assembly is a suitable choice. It continues to offer controlled conditions, including managed air flow and filtered HVAC systems. For many external-use devices, this option maintains quality while keeping costs low.

Device risk profiles that require ISO-classified environments

Certain devices need sterile assembly environments. Implants and surgical instruments serve as examples. Assembly for these items usually occurs in sterile and clean settings.

ISO-classified spaces should be used if a device affects health or if its performance is sensitive to particles. The cleanrooms at AMT provide validated controls suitable for assembling high-risk products.

Assemblies with Lower Risk Suited for Standard Controlled Settings

Standard environments are well-suited for devices intended for external use or components that will be sterilized later. They are cost-effective and adhere to good manufacturing practices.

Conducting assembly in non-ISO environments can accelerate the market launch of low-risk products. It delivers quality without incurring the high costs associated with stringent cleanroom standards.

| Setting for Assembly | Typical Use Cases | Key Controls | Impact on Cost |

|---|---|---|---|

| Cleanroom (ISO-classified) | Sterile disposables, implants, instruments for invasive procedures | Particle counts, HEPA filtration, gowning, validated procedures | Significant |

| Assembly in a White Room | External-use devices, components for later sterilization | Access control, hygiene protocols, filtered HVAC systems | Medium |

| Standard controlled environment | Prototypes, non-sterile subassemblies, low-risk parts | Basic controls for contamination, cleaning schedules, traceability measures | Minimal |

Quality assurance and microbiological controls in clean room assembly

Medical equipment safety and reliability are ensured by robust quality systems. Clean room standards are adhered to by AMT. These standards comply with ISO 13485 and the particular requirements of Singapore. Keeping detailed records and doing regular checks are key for meeting clean room rules across all manufacturing stages.

Validation schedules and documentation practices

Validation is planned and covers checking the environment, equipment, and processes. This encompasses particle and microbe counting, differential pressure logging, and temperature and humidity tracking. CAPA (Corrective and Preventive Action) traces are also documented. All these records help show that we meet the strict clean room rules for medical equipment.

Teams and Routines for Microbiological Inspection

Special teams focus on checking surfaces and air, and analyzing cultures. They look for trends, investigate abnormalities, and check if cleaning works. Their responsibility is to maintain stringent control over microbial levels. This assists in preventing contamination of sterile and sensitive medical instruments.

Controls for Traceability, Batch Records, and Packaging

For each medical device, we keep detailed records. This information covers materials, machine parameters, and operator details. When it comes to packaging, there are different steps based on the device’s risk. Sterile devices get special sterile packaging. Non-sterile ones get packaging that protects them but is not sterile. Each step makes sure everything is done right, from beginning until it’s sent out.

| Quality Element | Typical Activities | Expected Outcomes |

|---|---|---|

| Schedule for Validation | Regular qualification runs, revalidation following change control, seasonal checks of the environment | Validation protocols, acceptance reports, requalification certificates |

| Environmental monitoring | Air and surface sampling, particle counts, differential pressure monitoring | Daily logs, weekly trend charts, exception reports |

| Microbiology oversight | Culture testing, rapid alert investigations, cleaning efficacy studies | Microbial test results, corrective actions, method validations |

| Traceability | Tracking of material lots, records of operators and equipment, histories of digital batches | Complete batch records, serialized lot lists, audit trails |

| Control of Packaging | Runs of validated sterile packaging, checks on sealing integrity, verification of labeling | Packaging validation reports, sterility assurance documentation, shipment records |

Technical capabilities supporting medical equipment manufacturing

AMT mixes exact part tech with cleanroom assembly for medical gear making in %place%. These skills allow design teams to go from idea to approved item fast. This occurs without lengthy delays involving multiple companies.

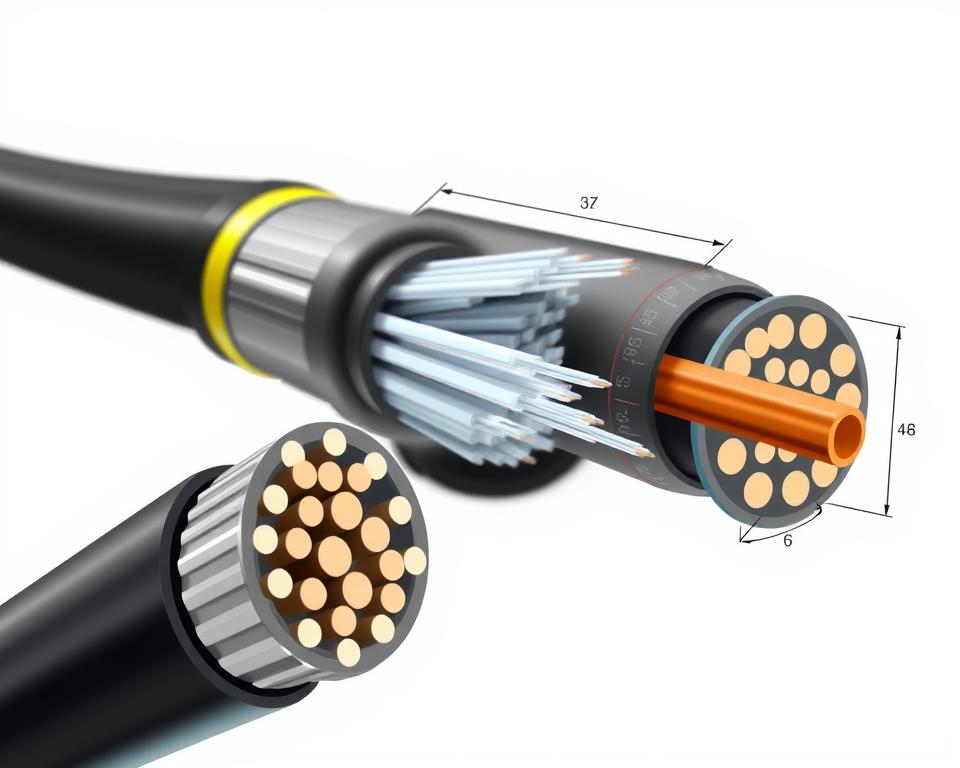

Metal and ceramic injection molding create detailed features that plastics can’t. Parts made from stainless steel and cobalt-chrome are produced for instruments and implants. Ceramic materials are used to create durable and biocompatible components for diagnostics and medical replacements.

Creating tools in-house ensures molds and dies are just right in size and smoothness. Rapid tool modifications significantly cut down on waiting times and lower the risk associated with parts that require a perfect fit. This also helps to control costs during scaled-up production.

3D metal printing makes making samples faster and allows for complicated shapes. This method allows engineers to verify the form, function, and fit before committing to mass production. Mixing 3D printing with usual molding accelerates the launch of new medical products.

The joining of dissimilar materials, such as metal, ceramic, and plastic, is made possible by these techniques. Joining techniques like overmolding are done in clean spaces to keep everything precise. This results in reliable assemblies for surgical instruments, diagnostic equipment, and implantable components.

Leveraging metal and ceramic injection molding, making tools, and 3D printing lets makers have one ally. This partner assists with sampling, validation, and the production of more sophisticated medical devices. It cuts down on dealing with many groups, keeps ideas safe, and makes getting official approval smoother.

Advantages in Supply Chain and IP Protection for Contract Manufacturing

The Singapore hub of AMT tightly integrates sourcing, production, and distribution. This provides support for the large-scale manufacturing of medical equipment. Workflows are centered to cut lead times and plan for large orders easily. For companies that require reliable components and consistent timelines, this approach offers distinct supply chain advantages.

Steady access to materials and effective cost management are ensured through strong partnerships in Asia. AMT collaborates with trusted vendors in Malaysia, Thailand, and Vietnam. This ensures the availability of necessary materials, components, and logistical support. A network like this simplifies shipping processes and guarantees on-time deliveries for time-sensitive projects.

AMT takes serious steps to protect clients’ intellectual property during contract manufacturing. The use of confidentiality agreements and controlled access to engineering files are standard practices. The safety of client designs and processes is also enhanced through segmented production lines. These actions meet the strict standards of regulated industries, ensuring secure tooling and prototype development.

Processes that are ready for audit and a skilled workforce assist in protecting intellectual property and meeting regulatory demands. Documenting design transfers, changes, and supplier details provides a record that can be traced. This mitigates risks when moving from prototype to mass production in a medical clean room.

Designed for scalability, the Singapore platform serves customers across more than 30 countries. This arrangement enables AMT to ramp up production without adding complexity to its processes. Consequently, companies can seamlessly transition from small-scale test runs to the large-scale production of surgical instruments and diagnostic devices.

Customers enjoy predictable planning and different choices for regional transport. This speeds up reaching the market. It is a smart move for medical equipment companies to partner with a provider that handles local logistics and ensures IP security. It provides an efficient method for global distribution while safeguarding proprietary technology.

Efficiency and Cost Factors for Clean Room Projects

The management of clean room projects centers on the factors that drive budgets and timelines. Teams consider clean room assembly costs versus benefits in quality and speed. The approach taken by AMT in Singapore exemplifies how expenses can be managed while adhering to standards.

The level of the cleanroom, the extent of validation, and the intensity of monitoring all influence costs. High levels require better HVAC and filtration, leading to higher initial and ongoing costs.

Validation and monitoring increase costs with tests and paperwork. These activities are crucial for complying with the standards set by agencies such as the US FDA. Costs of requalification and constant data gathering need planning.

Expenses are reduced by integrating manufacturing processes. This minimizes transportation needs and the requirement for multiple validations. This approach often saves money in medical device assembly.

Project timelines can be shortened by collaborating with a partner that offers full-service clean room solutions. This enhances coordination and traceability, reducing overall costs.

There are trade-offs involved in selecting the appropriate quality level. High-risk devices need more controlled environments. Less demanding conditions are suitable and more economical for simpler components.

Efficiency comes from strong quality systems like ISO 13485. Early regulatory alignment assists innovation while focusing on production readiness and validation.

To decide on a production setting, weigh all costs and rework risks. This balanced view ensures projects meet standards while saving money.

Industries and Product Examples Served by AMT

In Singapore and other Asian regions, AMT serves a wide range of medical clients. They produce components for hospitals, original equipment manufacturers (OEMs) of devices, and laboratories. They range from one-off prototypes to large batches for medical equipment.

Here are some ways AMT helps certain products and industries. They align their manufacturing capabilities with the requirements for quality and application.

Surgical and endoscopic components and assemblies

Items such as optics housings and grip modules for surgical use are manufactured by AMT. They work in cleanrooms to keep particles away during assembly. This work meets tough standards for size, surface finish, and clinical use.

Medical consumables and diagnostic components

They make disposable items like syringe parts and test cartridge houses. To comply with regulations, AMT integrates clean assembly with tracking systems. The diagnostic components they produce include items like sample ports and test holders.

Implants and high-precision parts

The production of implantable components using specialized materials and techniques is supported by AMT. For these components, they utilize metal and ceramic molding processes. Strict checks are in place for safety records and manufacturing history.

Examples, Patents, and Awards

AMT has 29 patents in 12 countries and 15 inventions. These patents and inventions underpin their distinctive tooling, metal processing, and assembly configurations. The awards they have received in metalworking showcase the skills that contribute to the manufacturing of medical devices.

| Product Type | Common Processes | Main Focus on Quality | Representative End Market |

|---|---|---|---|

| Endoscopic toolheads | Injection molding, cleanroom assembly, ultrasonic welding | Precision in dimensions, low generation of particulates | Surgical hospitals, ambulatory centers |

| Single-use consumables | Automated molding, medical consumables manufacturing, packaging | Assurance of sterility for sterile products, traceability | Labs for clinical use, care in emergencies |

| Diagnostic cartridges | Assembly of chambers for reagents, micro-molding, testing for leaks | Consistency from lot to lot, integrity of fluids | Diagnostics at the point of care, labs that are centralized |

| Components for Implantation | Finishing, metal injection molding, validated procedures for cleaning | Files on manufacturing history, biocompatibility | Dental, orthopedics, cardiovascular fields |

| Precision Parts (MIM/CIM) | Powder metallurgy, heat treatment, secondary machining | Reliability in mechanics, properties of materials | Medical device assembly – %anchor2%, instrument makers |

To Summarize

The operations of AMT in Singapore are a testament to high-quality medical device assembly within clean room environments. They are certified with ISO 13485, ISO 9001, and IATF 16949. They also have Class 100K cleanrooms. This capability allows AMT to safely manage complex diagnostic tools, surgical components, and implants.

In their approach, multiple processes are combined at a single location. It has on-site injection molding, tooling, MIM/CIM, and 3D metal printing. This minimizes the risk of contamination and reduces transport times. This method ensures safe medical device assembly in Singapore. It also protects intellectual property and improves teamwork with suppliers in Asia.

AMT provides strong quality assurance and options for microbiological control. Based on the risk profile of the device, teams have the flexibility to select the appropriate cleanroom classification. This balances cost, rules, and speed to market. For firms looking for a reliable partner, AMT’s medical clean room assembly is a smart choice. It offers the promise of scalable and reliable production within the Asian region.